One of the most obvious parts of the tank is the main gun barrel. From the 37mm on the M3A1 Lee to the massive 120mm gun on the Chieftain, the gun is the reason that the tank exists.

Far from being a simple tube, there are many parts and pieces of technology that are attached to the barrel. Not only do these affect the way the tank operates, they can also be used to identify tank types.

Of course, to understand the requirement for barrel accessories starts with an understanding as to how the gun works. The basic operation of a gun has not changed much since the days of muskets and black powder. A propellent (gunpowder, cordite, GB19T, etc.) is packed behind a projectile (lead ball, bullet, M829 “Silver Bullet” APFSDS, etc.). An initiator (Flint, primer, etc.) is used to set off the propellent which turns very quickly into gas (“explodes”). The change in physical state from solid to gas creates a huge pressure wave that pushes against the projectile and the sides of the breach. Since the projectile is in a tube (“barrel”) and the breach does not move; there is only one way for it to go. As the gas expands, it hurtles the projectile down the tube and out the end (“muzzle”). For comparison, a Brown Bess musket would send a 1 oz lead ball at about 1,500 fps (Feet Per Second) using about a hundred and twenty grains of black powder, with a chamber pressure of about 12,000 psi. A M1 Abrams M829 sabot round creates a pressure of over 81,000 psi generating a speed of over 5,100 fps shooting a 22lb projectile.

So much was done to manage the force and accuracy of the big tank guns. One of the first things added was the muzzle brake (or in the UK; barrel brake). There are a few reasons for the muzzle brake. The first reason was to direct the force of the expanding gases to the rear. This was done to counter the violent recoil that many guns had. This increased crew comfort and made the second shot faster and more accurate. It also meant that the recoil system did not have to be as large and robust as otherwise and would last longer before requiring maintenance. The next reason was to direct the blast to the sides of the vehicle. Without the muzzle brake, the force of the blast would raise dust, smoke, and dirt in front of the tank; impacting the ability to determine fall of shot (where you hit versus where you aimed) and taking more time to aim as you need to wait for everything to clear.

Sounds great but there are a few problems with muzzle breaks. First, it does increase the noise to the rear and sides of the gun. This could be a problem if you were firing in support of local infantry. Second, discarding sabot rounds often break open in the muzzle brake, which may impact accuracy (by as much as 50%). So, you will notice that modern tanks no longer use muzzle brakes. You may also notice that self propelled artillery such as the M109, still use them in order to push the blast to the sides where it is not visible to enemy artillery spotters.

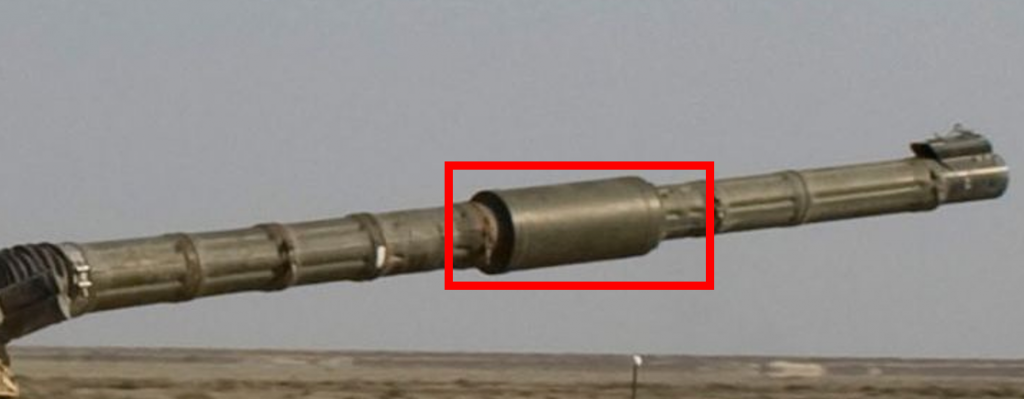

The next element is fumes management. When the propellent ignites; a great deal of gas is produced. Although most gas pushes out of the muzzle end of the barrel, some eventually goes back into the turret when the breach is opened. This blast of hot corrosive gas is less than ideal for the turret crew. To counter this, there are three common engineering techniques. The first (used by the French AMX-30, or M551 Sheridan) is to put a blast of compressed air into the breach just prior to opening. The second (used by the Russian T-14 Armata) is to put the gun is a sealed turret away from all the crew. The last (used by pretty well everything else from T54 to M1 Abrams) is to use a fume extractor (aka bore evacuator). This can be recognized by a “bulge” or “can” around the barrel, usually half way up. The principle of the fume extractor is that it is a sealed container attached to the barrel with holes drilled on an angle into the barrel. When the projectile is fired, it creates a high-pressure wave in front of it. As it approaches the fume extractor, it builds up pressure within the fume extractor. The projectile then causes a low pressure in the barrel as it passes through the fume extractor. The high-pressure gasses captured within the fume extractor then flood into the barrel behind the projectile pushing the gas and fumes out of the muzzle. If the tank is equipped with an automated breach opening device, the breech can be opened at the right time to pull air into the barrel from the turret, increasing the efficiency of the extractor.

With the ever-increasing accuracy of the tank’s main gun, more and more detail is factored into the ballistics computations. There are cross wind sensors on the turret. Air temperature and air pressure are considered. Even the characteristics of individual lots of ammunition are entered into the computer. With all of that, the calculations of how much the 7,300-pound gun barrel (M1A1 L/44) is not straight (barrel droop) has the next two features.

First consider, that very large metal barrel is not straight (although it is “mostly” straight”). It is affected by both gravity and heat. When the gun fires, the barrel gets hot. If the wind is blowing or it is raining, one side of the barrel is cooled by the environment. With any length of metal, if you heat one side and cool the other; it curves. Granted on a tank barrel, that curve is not much; but it is enough to affect accuracy when you are shooting 3 kilometers. To reduce this effect, barrel shrouds (or thermal sleeves) are introduced. This is just like a sweater for the gun. It keeps the weather out and the heat in. This limits the effect of the environment on the gun – keeping the barrel straighter. Some tanks such as the Chieftain use a canvas insulated cover while others (Leopard) cover the insultation with a metal sleeve.

Lastly, even with barrel shrouds; gun tubes change geometry as rounds are fired. As the barrel gets hotter; the gun curves a little bit towards the ground (Barrel droop). Since this cannot be stopped, ballistic computers take it into consideration. To help the computer understand how much the barrel is “drooping” a Collimator (better known as a “Muzzle Reference Sensor/System” – MRS). is attached to the end of the barrel. In general, it is a mirror. A laser is sent from inside the turret, the beam is bounced off of the mirror, and any distance out of true is measured and fed to the ballistics computer. The ballistics computer determines where the gun is pointing and adjusts the gunner’s targeting system to take that into account.

The technology used on the barrel has come along way since the first gun, armor, and tracks were integrated into a fighting vehicle. While at the Museum, you can see all these elements on the barrels of our collection of tanks: Plain barrel, Muzzle Brake, Fume Extractor, Barrel Shroud, and Muzzle Reference System. Enjoy your visit.