(Note: There are a large number of different types of tank ammunition. This article focuses only on Anti Tank ammuntion. Anti Infantry (Canister, HE) and anti bunker/material (HE, MPATs, ARM) are not covered in this article.)

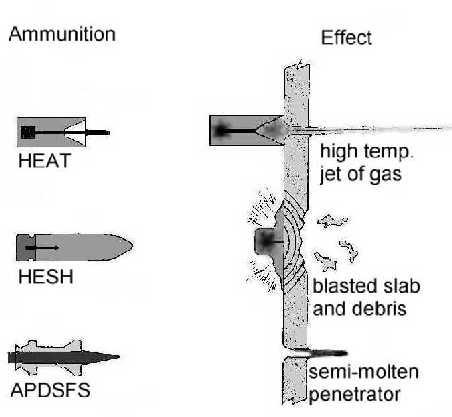

During and after the Cold War, anti-tank ammunition fell into two broad categories: Kinetic and Chemical. Kinetic rounds use sheer power and speed to punch through armour. Chemical or explosive rounds use the power of an explosive to defeat the target armour.

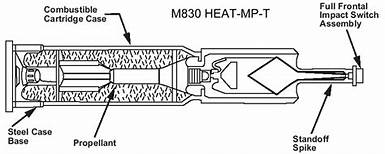

High Explosive Anti Tank (HEAT) (sometimes referred to as Hollow Charge or Shaped Charge) rounds evolved from the Swiss inventor Mohaupt who was able to demonstrate using a shaped explosive charge to increase penetration. The first HEAT weapon may be considered to be the British No 68 Rifle Grenade /AT. This was launched from a “Cup” launcher on the end of a rifle and was introduced in 1940. By the middle of that year, Germany had also adapted the KwK 37 gun of the Panzer IV and the Stug III to fire HEAT. HEAT was also used in the handheld Bazooka, PIAT, Panzerschrek, and Panzerfaust.

The basic design element of the HEAT round is the Munroe or Neuman effect. This states that a conical hollow in the forward end of an explosive will greatly increase the penetration effect. This works by concentrating the explosive force into a jet of force along the axis of the hollowed area. A thin sheath of copper (or other materials but copper is most prevalent) can be added and the plasma jet formed by the copper will move at 14 km/s and reach a temperature of 925C. This can penetrate more than seven to ten times the diameter of the charge in hardened steel armour.

There are two significant additions to modern heat rounds. The first is the addition of fins. A spinning HEAT round from a rifled barrel is less effective than a stable one so the fins are used to keep the round on target. The second is the standoff initiator. This is a rod that holds the imitator ahead of the round so that the explosive jet “stands off” far enough to properly form.

There are three primary defensive methods for protecting against HEAT rounds. The first is the use of stand-off armour. This is light armour situated in front of the main armour. This causes the HEAT warhead to explode early and it disrupts the formation of the jet. The bar or slat armour used by the Canadian Forces in Afghanistan is an example of this armour. In the early 1980s, the Israel Army developed the first successful Explosive Reactive Armour (ERA). This is a brick made of a slab of explosive fronted by a steel plate. These bricks are attached to the armour of the tank. When a HEAT round detonates, the formed jet of plasma also detonates the ERA explosive. This explodes out and away from the tank – pushing the plasma jet away from the tank. The third defense is Composite Armour. This is armour made from a number of different materials sandwiched together. The first was “Chobham” armour developed in the 1960s in England. The original used a mix of steel and ceramic tiles but modern versions can also include carbon nanotubes, glass beads, spaces, and even rubber.

There is a new set of active protection systems beginning to be fielded such as Trophy and Quick Kill, but these are focused on defeating HEAT missiles and not HEAT gun rounds. HEAT rounds are faster than HESH but slower than kinetic penetrators often around the 1000m/s muzzle velocity.

Over time, HEAT rounds (although remaining popular with missiles and handheld weapons) have been outpaced by Kinetic rounds for anti tank work.

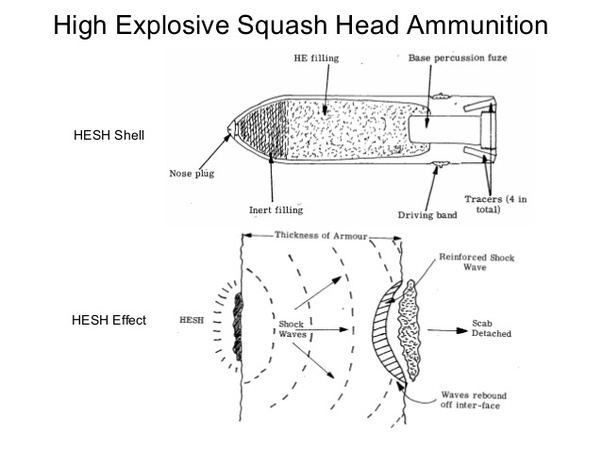

The second type of Chemical rounds that were invented were High Explosive Plastic (HEP) or High Explosive Squash Head (HESH). Unlike HEAT rounds that were used by most countries, HESH rounds were popular with Britain and countries that purchased British vehicles. A HESH round is a thin metal shell containing an amount of plastic explosive and a fuse on the base. In principle, the shell breaks open when it hits the target’s armour, the plastic explosive “pancakes” against the armour and explodes when the fuse hits the armour. The pancake of explosive explodes and sets off a shock wave through the armour. This shock wave breaks off pieces of the armour (spall) which then travel through the interior of the target causing causalities, breaking equipment, and exploding ammunition or fuel.

HESH rounds can be defeated by either using composite armour or spall liners. A spall liner is a Kevlar or similar cloth that is attached to the hull of the vehicle and minimizes the spalling effect. A second reason is that the Kinetic rounds are more accurate when using a smoothbore gun – HESH is more accurate with a rifled barrel.

HESH rounds rely on the power of the explosive to destroy the target so they tend to be slower than their kinetic cousins – usually less than 800 m/s.

HESH rounds are still routinely carried for demolition and anti-bunker use.

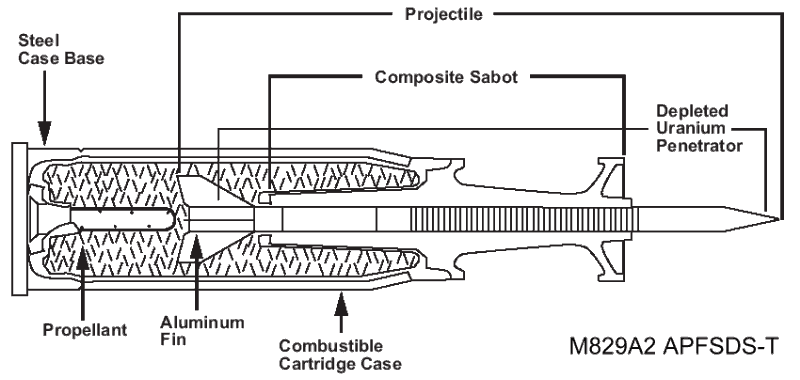

The modern antitank round of choice is Armour Piercing Discarding Sabot Fin Stabilized (APFSDS) which is referred as SABOT or FIN if you are British. The Sabot round is a long (almost 1m) and thin (2-3 cm) pointed rod of a dense metal (tungsten or similar) with stabilizing fins on the end. It is like a very robust dart. The dart is encased in three or four plastic or aluminum “Sabots” (French for Shoe) when in the shell or in the barrel. When the round leaves the barrel of the gun, the sabots fly off and the dart continues to the target.

The design of the SABOT round utilizes two important rules of physics. First, the speed of the round is proportional to the bore size. So, a 120mm gun round can go faster than a 105mm gun round. Secondly, penetration is inversely proportional to the diameter of the penetrator; much like a needle can go into a piece of wood where a brick with the same force will not. A Sabot round uses the breadth of the dart and sabot combination for maximum force and speed and the discards the sabot so that penetration is only the pointed dart. The length of the dart ensures that there is maximum kinetic force when it hits the target.

When a Sabot round hits the target, the force is so high that the tip of the dart turns to plasma and literally burns its way through the armour. Modern APFSDS can reach muzzle velocities of up to 1700 m/s and burn through 2000 mm of RHA. These rounds can be “ballistically flat” for 1600m which is how far they can go before gravity has a significant effect on their trajectory.

The United States has fielded the M829 family of Depleted Uranium APFSDS rounds for the M1 Abrams since 1982.